What’s the different between PVDF and Powder coating?

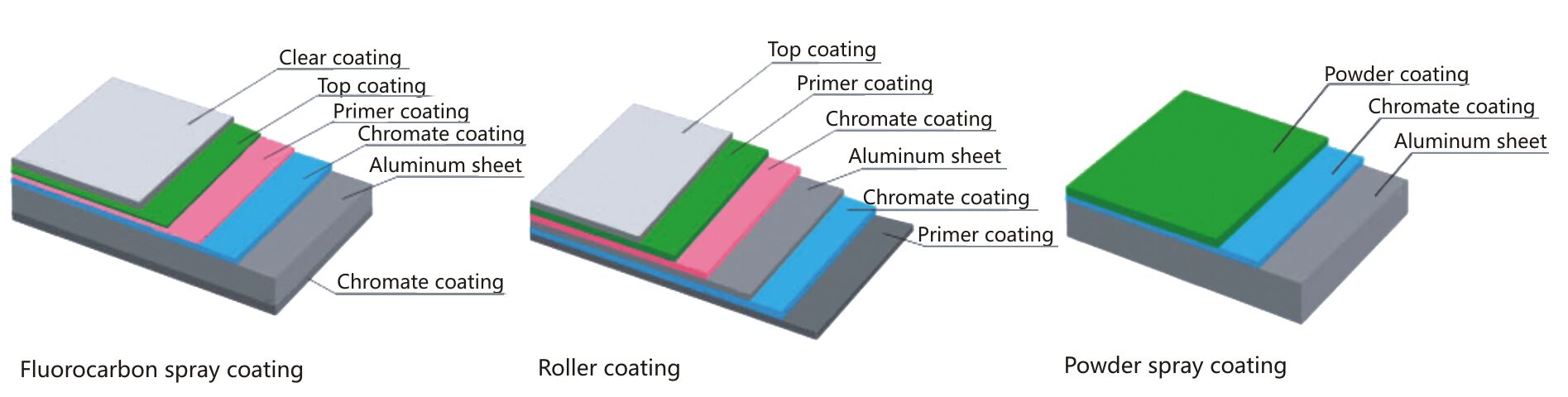

Spray coating is a very important process in the manufacture of aluminum wall panel (aluminum cladding). Electrostatic spraying uses electrostatic spray guns for spraying. Strictly speaking, electrostatic spraying is divided into electrostatic liquid spray coating (Polyvinylidene fluoride, short for PVDF) and electrostatic powder coating (powder coating). Generally, in accordance with different spraying objects and specific effects, the spraying methods are relatively different as well. Each of them has its own characteristics

DIFFERENCES

- Different paint materials

PVDF spray coating uses a well-tuned (modulated) paint, which is a fluid, and powder coating uses a powdered solid.

- Different spraying sites

PVDF spray coating is mainly carried out in a paint booth, and powder spraying is carried out in the powder spraying chamber.

- Different ways of working

PVDF spray coating uses a diaphragm pump or a plunger pump to apply pressure and static electricity for spraying. The powder coating is sprayed by shaking or inhaling, and electrostatic powder is sprayed on the gun mouth.

- Different drying methods

Drying of PVDF can be both natural leveling drying and baking. Drying of Powder coating is mainly by baking.

- Different spraying effects

After natural leveling drying of PVDF, the coating film is very thin. The powder coating has good performance of anti-corrosion, high adhesion, and thick coating film, but it tends to discolor (color fade) if exposed to sunlight for a long time in the exterior area.

We normally suggest our customer use PVDF coating in the conditions of exterior usages, especially for the places with strong sunlight, or the places are humid like the seashore. And powder coating can be used for interior decoration.

- Different price

For the same brand, the price of powder is generally 10 dollars cheaper than paint.

SIMILARITY

The same treatment before spraying.

The pre-treatment of the process is mainly anti-oxidation treatment and chromate treatment, which aim to clear oil, dust, and rust on the aluminum plate surface. The treatments not only prevent the rust but also increase the adhesion of the paint film.

SUMMARY

Powder coating has the advantages of high efficiency, energy saving, less pollution, environmental protection, high paint utilization, and good coating performance. The disadvantage is that it is not resistant to sunlight.

The advantages of PVDF spray coating is high brightness, thin coating and stable color, strong weather resistance, not easy to fade, and discoloration.

We need to choose different spray coating methods according to specific products and requirements. In the aspect of the aluminum wall panel, powder coating can be used to produce special effects such as various wood grain or stone pattern.

(Video about Chromizing & PVDF Spray coating of aluminum panels)