Project Description

(Last Updated On: August 14, 2018)| ITEM | DETAILS |

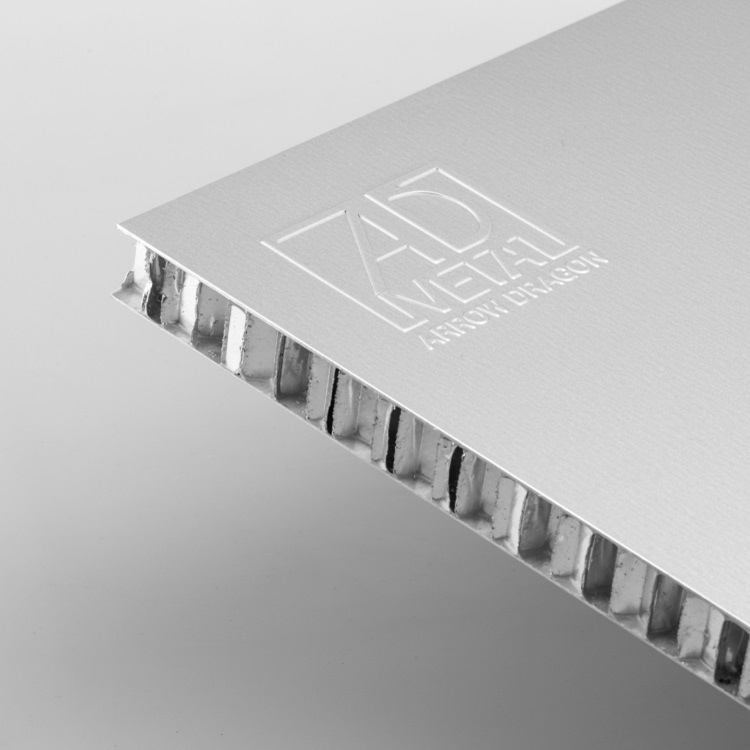

| Aluminum face plate | Fluorocarbon roller coating panel. |

| 3003 H24, or 5052 H14 aluminum alloy as base materials. | |

| Thickness of 0.05mm- 1.2mm | |

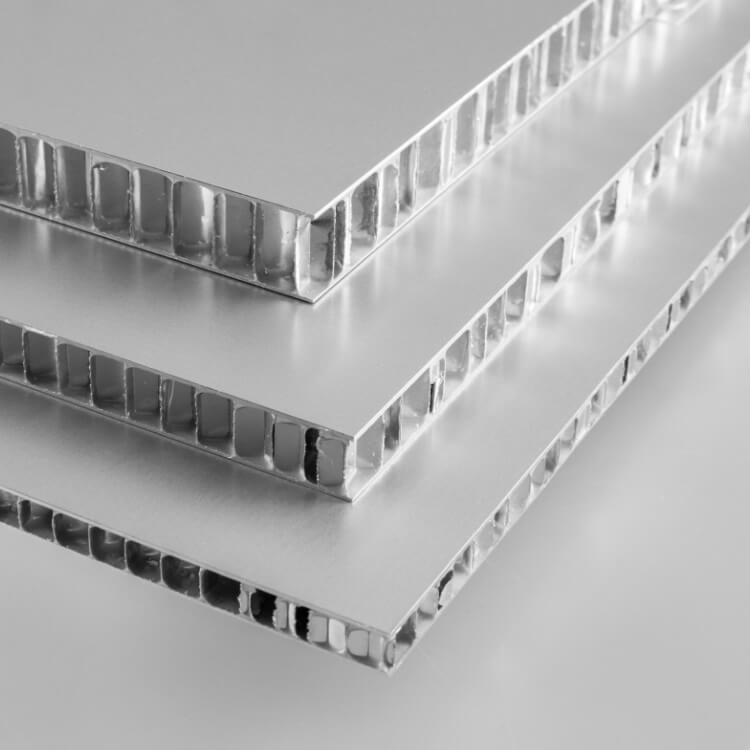

| Aluminum base plate | Thickness of 0.5mm – 1.2mm |

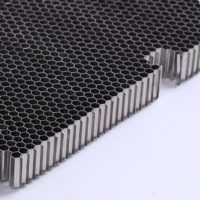

| Aluminum honeycomb core | 3003 H24 hexagon aluminum honeycomb core, |

| aluminum foil thickness 0.04-0.07mm, side length of 4-7 mm. | |

| Adhesive | Bio-component polymer epoxy adhesive film & Bi-component modified epoxy resin. |

| Dimension | 500mm<L<12000mm, |

| 500mm<W<2000mm | |

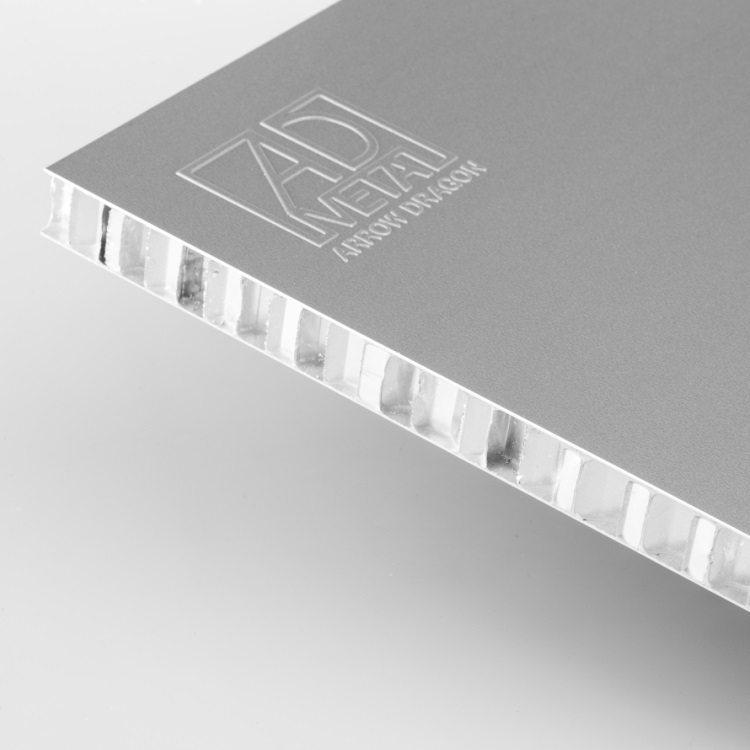

| Surface treatment | PVDF, powder coating, roller painting, anodizing, |

| Color | RAL color, Pantone color |

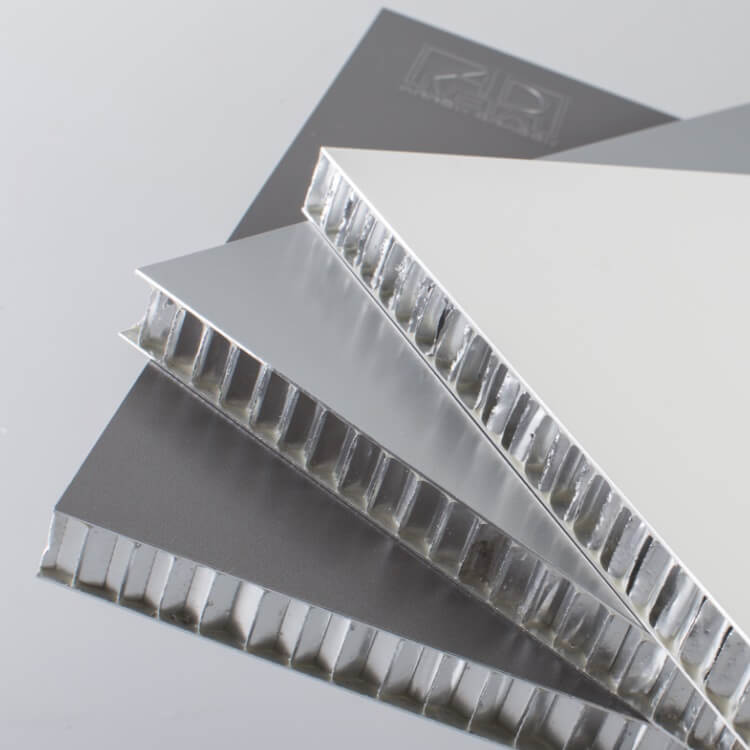

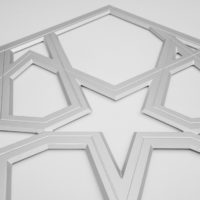

| Shape | Flat, cambered, perforated, double curved, triple curved, spherical and customized shaped. |

Arrow Dragon aluminum honeycomb panels are mainly used for building interior or exterior wall decoration of the building. The panels are made of imported high-quality raw materials with precision machining. The surface of the panel is printed by advanced pre-roll coating fluorocarbon technology which can keep thirty years without discoloration. With the fully automatic honeycomb panel composite production equipment, we compound bio-component polymer epoxy adhesive film and bi-component modified epoxy resin by imposing high-pressure and high-temperature under fully enclosed dust-free environment, making sure the aluminum honeycomb panel paste firmer. The panel is straighter, more flexible for bending, and more reliable in quality.

The arc plates, groove plates, trapezoid plates or other special-shaped plates can be designed and fabricated as the requirement. All of the arc-shaped, L-shaped, U-shaped or other non-planar shaped plates are a one-time molding through the mold. The same project uses the same batch roll coated aluminum coil, to avoid the color different problem. Aluminum honeycomb plate belongs to a kind of high quality, lightweight, high strength, luxurious and gorgeous green decorative materials.

FEATURES

- Extremely lightweight.

- Excellent strength, good rigidity, and super stiffness.

- High resistance to moisture and corrosion.

- Fire resistance and shockproof.

- Heat insulating and sound proof.

- Easy to be processed into any artistic designs or unique shapes.

- Easy and safe for installation.

- Diversity color choices bring elegant decorative effect.

- Cost efficiency.

(Production Processing of Aluminum Honeycomb Panel)

APPLICATIONS

Aluminum honeycomb panels are widely used in our daily life, not only in architecture area but also in transportation and other areas.

For architecture: façade cladding and roofing, soffit, column cover, ceilings of the building. Mobile platforms for scenes or audiences.

For ceilings, walls, column coverings, floors, doors, platforms, all kinds of furniture and outdoor balcony partitioning of cruise ships, fast ferries, luxury marine, yachts and other special vessels.

For interior construction, for cleanrooms, partitions, lightweight containers, cabins for the machine tool, wind tunnels, lifting platforms, lifts.

For wall cladding and roofing in the rail vehicle, for superstructures for lorry, for cabins, for doors and flap systems.

For furniture, work table, and countertop.

For floating cover for the oil tank.

For solar energy.

For bus stop shelter, sunshade, and awning platform.

For platen, fixture, and infill panel.

For machine enclosure, machining surface, and container cladding.